Inquiry

Form loading...

-

Phone

-

Wechat

-

Whatsapp

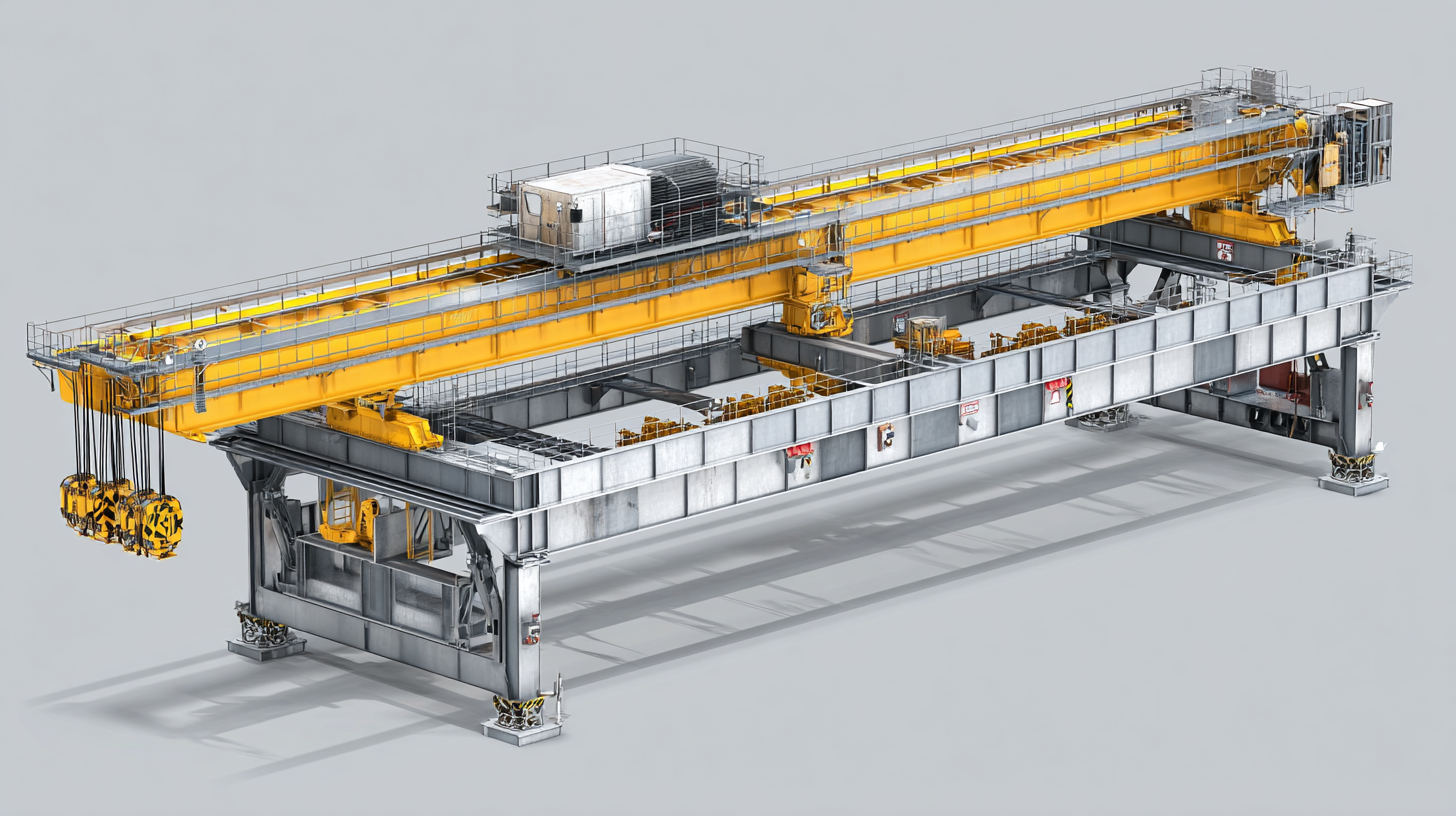

In the realm of modern construction, the evolution of lifting equipment has been pivotal to enhancing efficiency and safety on job sites. One of the standout innovations in this field is the advancement of Girder Crane technology. These cranes play a crucial role in moving heavy materials, providing significant support in various construction tasks. As projects grow in complexity and scale, understanding the latest developments in Girder Crane design, functionality, and automation becomes essential for industry professionals. This article aims to explore the key advancements in Girder Crane technology, highlighting their benefits and applications, while offering insights into how these improvements are transforming the construction landscape. By delving into the intricacies of Girder Crane systems, we can appreciate their impact on modern construction practices and the future of lifting solutions.

Innovative features in modern girder cranes have significantly enhanced their efficiency, making them indispensable in contemporary construction. According to a recent report by the International Journal of Robotics and Automation, the integration of IoT technology into girder cranes has led to an average increase in operational efficiency by up to 30%. This enhancement is largely due to real-time data transmission which allows operators to monitor crane performance and positioning more accurately, reducing downtime and improving safety measures on-site.

Additionally, advancements in materials science have led to the use of lighter yet sturdier materials in girder design. For instance, the adoption of high-strength steel and composite materials has resulted in cranes that can carry heavier loads while requiring less energy to operate. A study conducted by Construction Equipment Magazine highlights that modern girder cranes equipped with advanced energy-efficient motors can reduce energy consumption by nearly 25%, showcasing the industry's commitment to sustainability. These innovations not only streamline operations but also contribute to reducing the environmental impact of construction activities.

The integration of smart technologies in girder crane operations is revolutionizing the construction industry. With advancements such as IoT sensors, AI, and real-time data analytics, these cranes are becoming smarter, safer, and more efficient. IoT sensors collect vital information about load weights and environmental conditions, allowing for precise monitoring and adjustments during operations. This means that operators can make informed decisions, reducing the risk of accidents and enhancing overall productivity.

Tips: When utilizing smart technologies in crane operations, ensure that all sensors and systems are regularly maintained and calibrated. This will maximize their effectiveness and prevent potential malfunctions. Additionally, investing in training for operators on how to leverage these technologies is crucial for maximizing their benefits.

Furthermore, the implementation of AI algorithms in crane management systems can optimize lifting patterns and sequences in real-time. By analyzing data, these systems can predict the best course of action, minimizing downtime and enhancing workflow. As the construction industry moves towards more automated solutions, embracing these advancements will not only streamline operations but also result in significant cost savings over time.

Tips: Always keep your software updated to take full advantage of new features and security improvements. This ensures that you benefit from the latest advancements in crane technology while protecting your operations from vulnerabilities.

The evolution of girder crane technology has significantly transformed modern construction practices. A comparative analysis between traditional and advanced girder crane designs highlights notable differences in efficiency, safety, and operational flexibility. Traditional cranes, while reliable, often exhibit limitations in load capacity and maneuverability. According to a report by the International Federation of Cranes, traditional models can handle loads of up to 10 tons, but their operational speed can be hampered by outdated motor systems and control mechanisms.

In contrast, advanced girder cranes, which incorporate smart technology and enhanced engineering materials, can support loads exceeding 20 tons with improved speed and precision. The integration of IoT and automated control systems allows these cranes to operate with minimal human intervention, effectively reducing the risk of operational accidents. A study from the Global Construction Report indicates that projects utilizing advanced cranes can experience a 30% decrease in construction time and a significant boost in overall productivity. This progression not only demonstrates technological advancement but also emphasizes the importance of selecting the right crane design to meet the demands of contemporary construction projects.

| Feature | Traditional Girder Crane | Advanced Girder Crane |

|---|---|---|

| Load Capacity | Up to 10 tons | Up to 50 tons |

| Operating Speed | 0.5 m/s | 2 m/s |

| Control System | Manual | Automated with remote control |

| Energy Efficiency | Standard | High efficiency with regenerative drives |

| Maintenance Requirements | Frequent | Minimal due to advanced components |

| Safety Features | Basic safety mechanisms | Integrated advanced safety systems |

| Height Adjustment | Manual | Automatic adjustments |

| Installation Time | Longer | Faster setup |

The advent of automation in girder crane technology has significantly transformed the construction industry, enhancing both safety and productivity. Automated systems, such as remote-controlled cranes, reduce the need for manual operation, thereby minimizing the risks associated with human error. Construction sites often involve complex operations where the presence of workers in hazardous areas can lead to accidents. With automated cranes, tasks can be performed from a safe distance, ensuring that operators are not exposed to potential dangers from heavy lifting operations or falling debris.

Furthermore, automation contributes to increased productivity by streamlining operations. Advanced algorithms and sensors allow cranes to execute precise movements and adjust loads effectively, which enhances the speed of construction processes. Projects that once took weeks can now be completed in a fraction of the time, as automated systems can work continuously with greater efficiency. This not only helps meet tight deadlines but also reduces labor costs, as fewer workers are needed on site. The combination of safety enhancements and productivity gains underscores the vital role of automation in modern construction, making girder cranes more reliable and effective than ever before.

The landscape of construction is undergoing a transformative shift with the emergence of sustainable practices and advanced technologies. Girder cranes, pivotal in this evolution, are now integrating eco-friendly materials and energy-efficient systems. These cranes are designed to minimize their carbon footprint by incorporating lighter materials that reduce fuel consumption and enhance operational efficiency. Additionally, advancements in electric and hybrid models are becoming more prevalent, allowing construction sites to operate with reduced emissions, aligning with global sustainability goals.

Looking to the future, the integration of smart technologies within girder cranes is set to revolutionize their functionality. Features such as IoT connectivity, artificial intelligence, and autonomous operations are positioning these machines at the forefront of modern construction. These innovations not only enhance precision and safety but also streamline project management processes by allowing real-time monitoring and data analysis. As the industry increasingly prioritizes sustainability, these advanced girder cranes will play a crucial role in shaping more efficient and environmentally responsible construction practices.